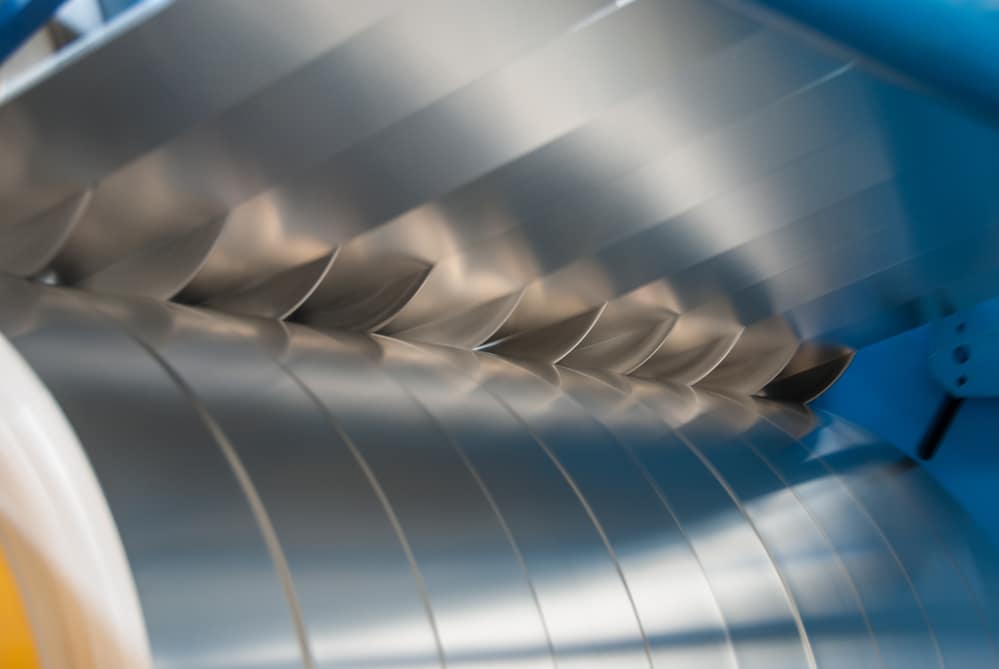

Metal Coil Steel Slitting

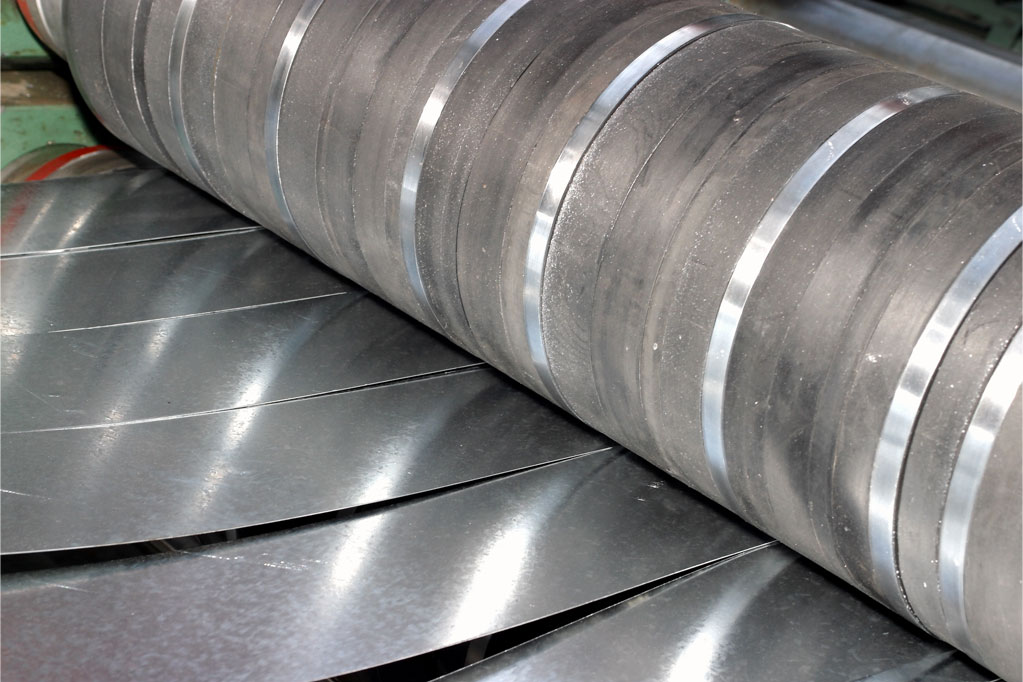

Precision metal coil steel slitting, often referred to as rolled steel slitting, is a process by which master coils (typically wide coils) of stainless steel and other metals are fed lengthwise through a slitter and cut into narrower coils. Each of the finished slit widths is known as a strand, and then undergoes the recoiling process to produce a finished slit coil with a much narrower width.

Precision metal coil steel slitting, often referred to as rolled steel slitting, is a process by which wide coils of metal are fed lengthwise through a slitter and cut into narrower coils. Each of the finished widths is known as a strand and is recoiled to produce a finished width narrow slit coil.

Consolidated Metal Service, Inc. adds value by being able to make these adjustments to our steel slitting machines and being able to deliver rolled steel in various widths depending upon the needs of a particular industry or customer.

Read more about our Steel Slitting process.

There are three main parts to a steel slitting machine: an uncoiler, the slitter and a recoiler. The key to optimizing the quality of the steel slitting process is in the setup. Ensuring all elements are exactly aligned, cutter spacing and slitting knife clearance are set correctly, quality tooling and sharp knives are being used, are all critical components of a high-quality setup.

Our slitting process offers the following benefits:

- Reduced time-to-delivery

- Reduced scrap

- Reduced costs

- Streamlined material flow

We also offer steel edge conditioning which is a process in which the edge of a steel coil is rolled to a desired shape – round, modified, etc. See our Coiled Steel Edging machine details.

Consolidated Metal’s Steel Slitting Services

Consolidated Metal Service, Inc. prides itself in being one of the leaders in sheet metal processing and slitting for over 40 years. You can be certain our products and services will meet all your expectations and demands for your OEM and industrial needs.

We offer our high-speed steel slitting services for the following list of metals in various material thickness:

- Heavy Gauge Aluminum

- Brass

- Copper

- Hot Rolled Steel (HRP&O Steel)

- Tin Plate

- Cold Rolled Steel

- Galvanized Steel Sheet

- Painted Materials

- Electro-Galvanized Steel

- High Carbon Steel (Annealed & Tempered)

More About Us

As a leader in metal processing and slitting services, you can trust Consolidated Metal Service, Inc. to provide precision coil slit products for steel coils and for a variety of other metals as well. Our products also come in many different widths and can be used for a wide range of industries. You can either choose from our inventory or bring us yours. Either way, we can meet your precise requirements with coil slits:

- as narrow as .250 inches

- as wide as 48.00 inches

In addition to slitting all types of high carbon steel as well as HSLA steel and other metals, CMSI can provide:

- Cold Rolled Steel Edging – removing slitting burrs from the edge of steel coil and rolling the edge into a desired shape.

- Cold Rolled Steel Toll Processing – slitting and edging your coiled metal inventory which you can drop-ship to our location.

- Local & Cross-Country Shipping – providing local delivery with our own fleet and cross-country shipping through national providers.

Contact us for details about a specific project and let our experts provide you with a no-obligation cost estimate on your rolled steel slitting needs. We take great pride in preparing our narrow-slit service and slit material to meet your specifications.

Happy to accommodate orders of any size!

Request a quote

Contact us for details about a specific project and let our experts provide you with a no-obligation cost estimate on your rolled steel slitting needs.