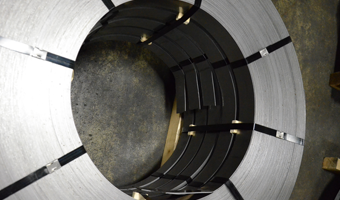

Types of Hot Rolled Steel

There are two basic ways to manufacture steel: hot rolling and cold rolling. Both hot rolled steel and cold rolled steel are pre-fabrication techniques used for making a variety of products. Unlike cold rolling, which requires further processing in cold reduction mills followed by annealing and/or tempers rolling, hot rolled steel is heated and given a rougher surface finish.

Types of Steel

Here are the types of steel products that Consolidated Metal Services Inc. offers:

- AISI 1010 Hot Rolled Steel

- 1020 Hot Rolled Steel

- 1018 Hot Rolled Steel

- Hot Rolled Pickled and Oiled Steel

- Hot Rolled Bar Stock

- A36 Hot Rolled Steel

- HSLA (high strength low alloy)

- 1008 Steel

- and many more!

Hot rolled steel is typically used for construction, railroad tracks, sheet metal, and other applications that do not require attractive finishes or precise shapes and tolerances. Finished products of the steel manufacturing process offer high formability and corrosion resistance.

Our inventory includes a wide range of steels with varying chemical compositions such as alloy steel and carbon steel both of which offer more effective yield strength than some grades of steel. ASTM A36, for example, is a low-carbon steel that is one of the most popular in the steel market due to its wide range of structural applications.

In addition to custom slitting metals, other services provided by Consolidated Metal Service, Inc. include:

- Cold Rolled Steel Edging – removing slitting burrs from the edge of steel coil and rolling the edge into a desired shape.

- Cold Rolled Steel Toll Processing – slitting and edging your coiled metal inventory which you can drop-ship to our location.

- Local & Cross-Country Shipping – providing local delivery with our own fleet and cross-country shipping through national providers.

Requesting a quote is a great way to get started

We’re happy to answer any questions you might have about our services and products…